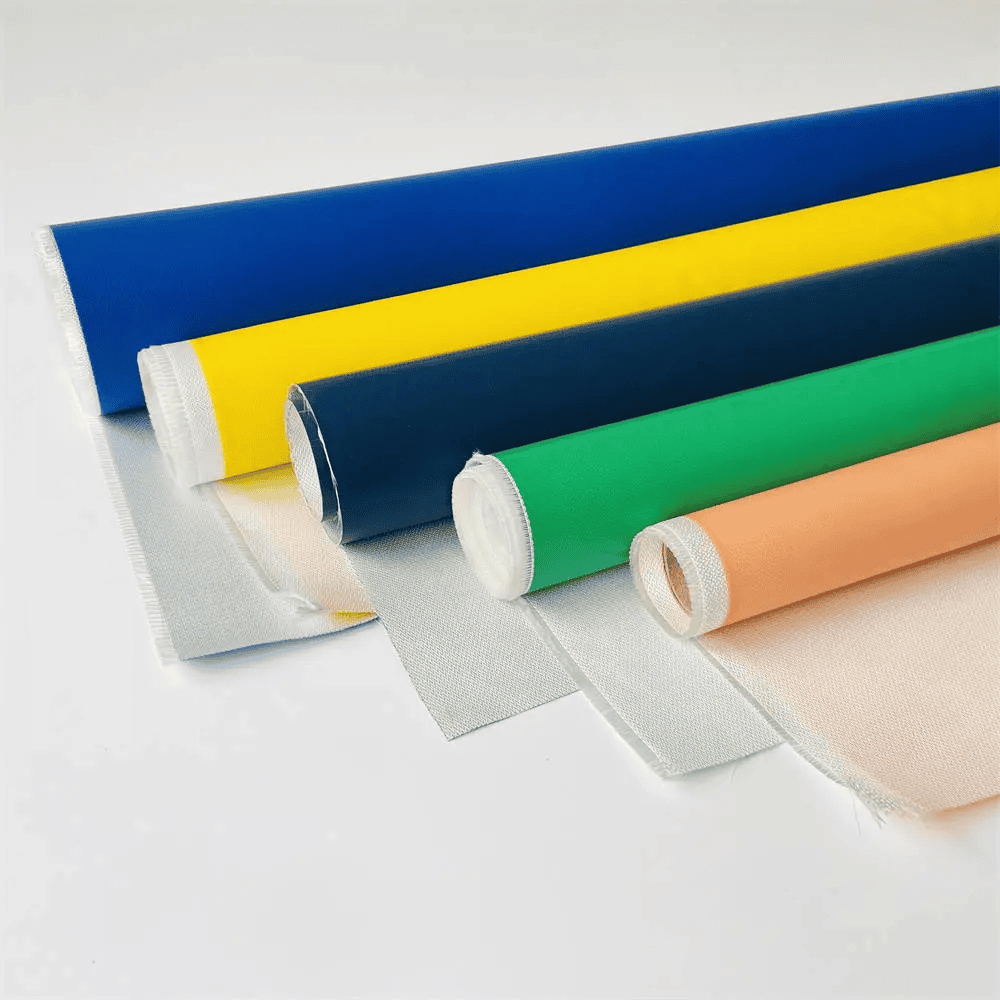

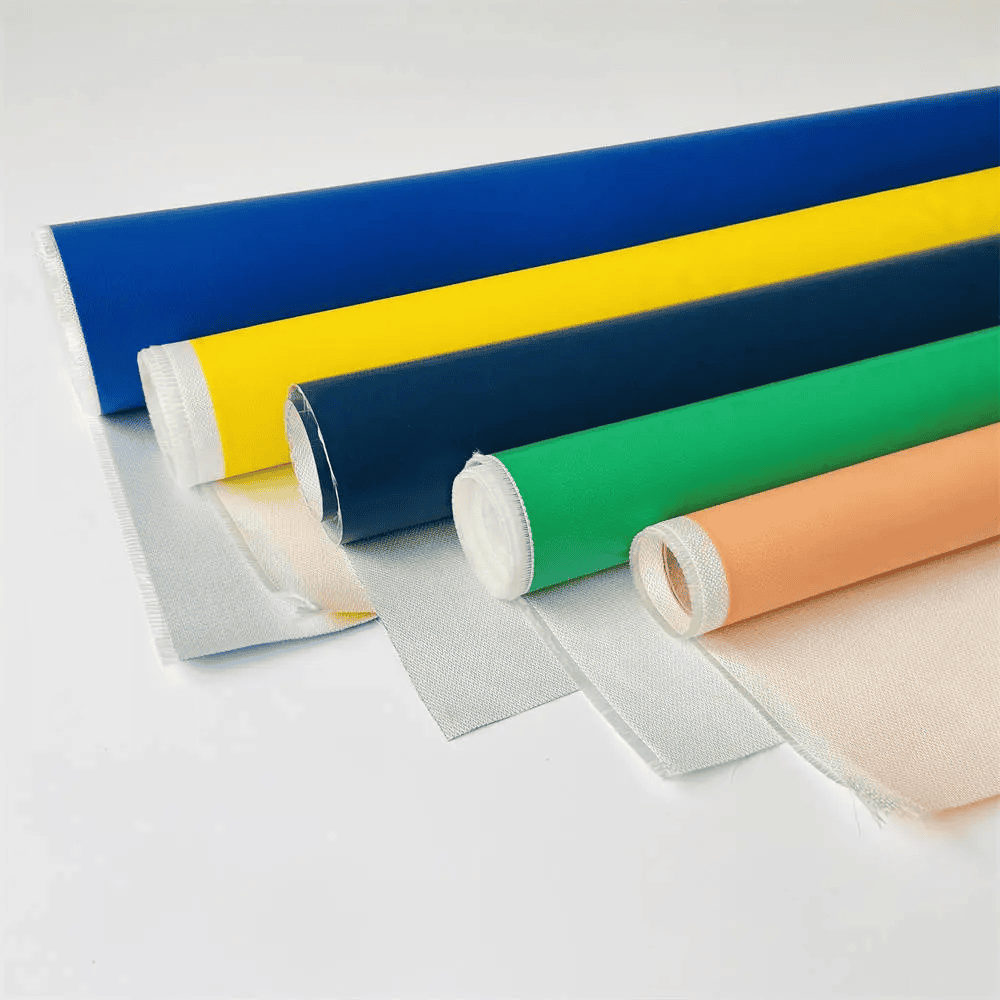

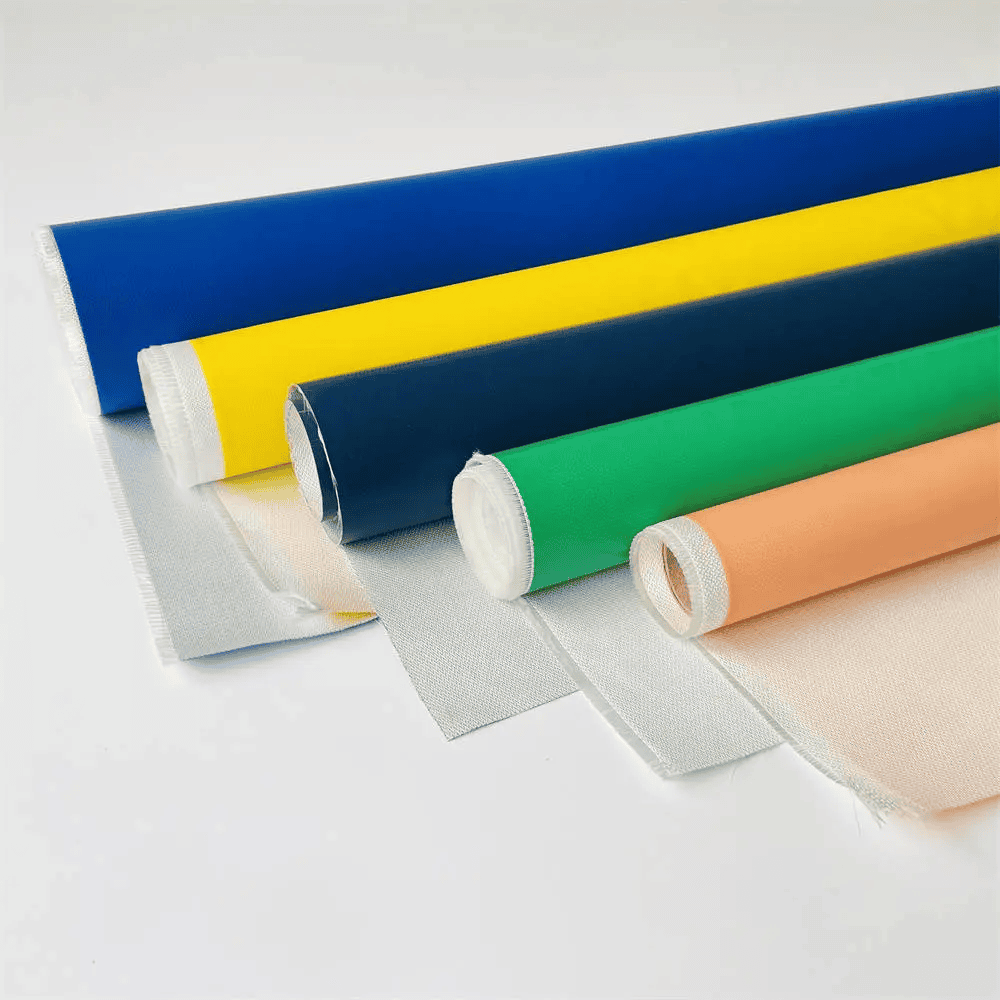

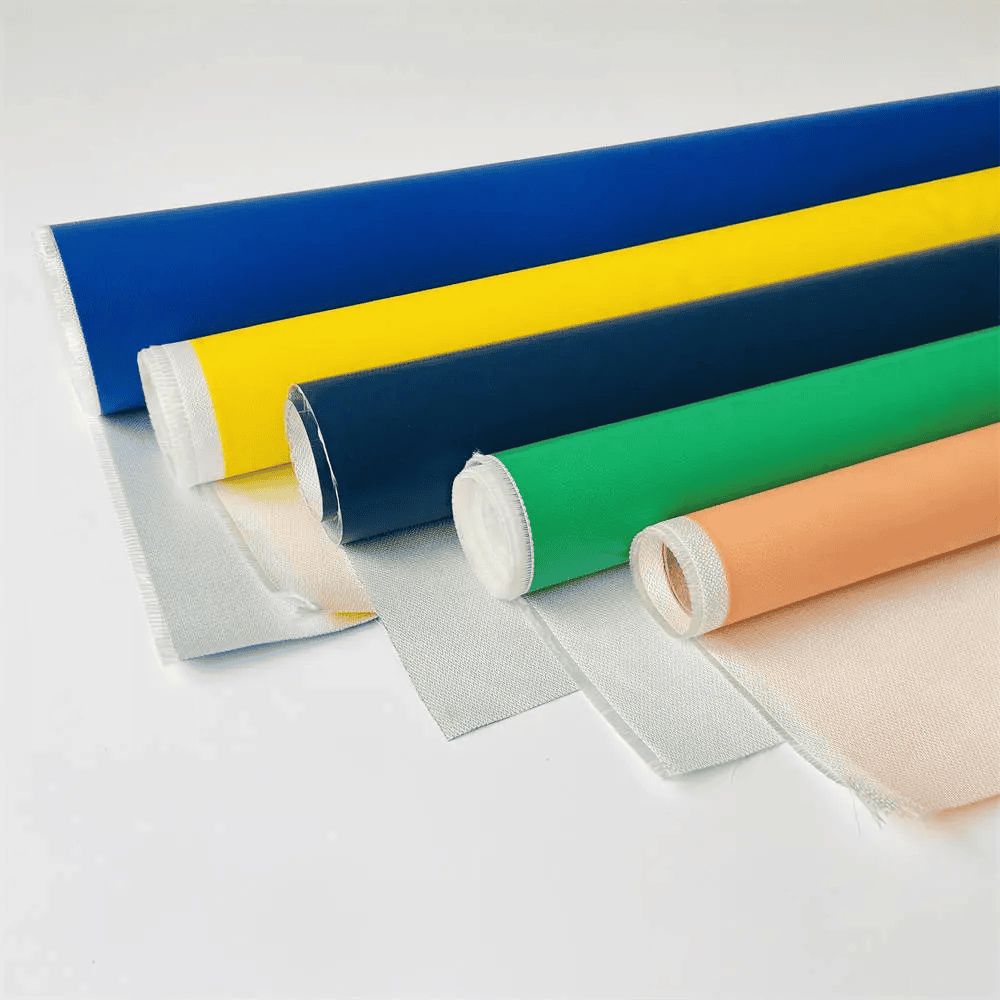

Silicone Coated Fiberglass Fabric

Silicone Coated Fiberglass Fabric is a lightweight, durable, heat and flame resistant material that is used for a variety of industrial applications. It is made from a combination of glass cloth and silicone with the glass cloth providing the tensile strength and the silicone providing the waterproofing and flame resistance. This material is highly versatile and can be used for insulation, weatherproofing, and many other applications.

This combination allows it to merge the best qualities of both materials:

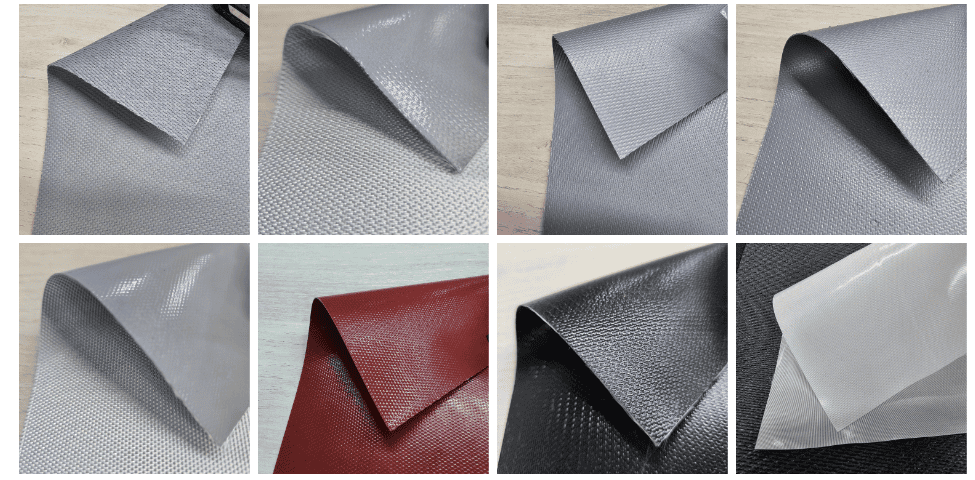

- Strong yet Flexible: It inherits the dimensional stability and high tensile strength of fiberglass while gaining the flexibility of silicone rubber. This allows it to be easily wrapped, draped, or fitted over various shapes and equipment.

- High and Low-Temperature Resistance: It can be used continuously in a wide temperature range, typically from -70°C to 280°C (-94°F to 536°F), making it more than capable of handling common industrial heat and outdoor cold environments.

- Excellent Protective Properties: The silicone coating makes its surface waterproof, oil-repellent, and resistant to many chemicals. It also provides great electrical insulation.

- Safe and User-Friendly: Its smooth surface prevents the release of airborne fibers, which can happen with raw fiberglass, making it less irritating to the skin and safer to handle during installation and fabrication.

The Most Common, Everyday Applications

Thanks to these practical characteristics, silicone-coated fiberglass cloth plays an indispensable role in many down-to-earth industrial and commercial fields. Here are its most common uses:

-

The "Protective Blanket" for Welding and Cutting (Welding Blankets / Fire Blankets) This is one of its most well-known applications. During welding, grinding, or torch-cutting, sparks and molten splatter can easily ignite nearby materials or damage equipment. Spreading a silicone cloth blanket under or around the work area effectively contains these hazards. It serves as a safer, more environmentally friendly alternative to traditional asbestos blankets and is far more heat-resistant than canvas tarps.

-

The "Insulation Jacket" for Pipes and Equipment (Removable Insulation Covers) Many pipes, valves, flanges, and exchangers in factories require insulation to reduce heat loss or prevent worker burns. While traditional insulation is effective, it's difficult to remove for maintenance. Removable insulation jackets, made with a silicone cloth outer layer and an insulating fill (like glass wool), are like custom-fitted "winter coats" for equipment. They are not only great insulators but also waterproof, oil-resistant, and easy to clean. When maintenance is needed, you simply unfasten the buckles, making inspections and repairs incredibly convenient.

-

The "Flexible Connection" in Industry and Construction (Fabric Expansion Joints) In systems like ventilation ducts and dust collection pipelines, thermal expansion, contraction, and equipment vibrations require flexible connections to compensate for movement and absorb shock. Silicone cloth is the ideal material for fabricating these non-metallic expansion joints. It can withstand the system's temperature and pressure while remaining flexible, ensuring the integrity and longevity of the ductwork.

-

Versatile "Protective Curtains" and "Seals"

- Smoke Curtains / Fire Curtains: In the fire safety systems of large shopping malls, warehouses, and atriums, smoke curtains made from silicone cloth are used to channel and block the horizontal spread of smoke during the early stages of a fire, buying valuable time for evacuation.

- Industrial Furnace Curtains: Hanging strips of silicone cloth at the openings of industrial ovens, furnaces, and kilns effectively reduces heat loss, leading to significant energy savings.

- Gaskets and Seals: Leveraging its temperature and chemical resistance, the material is often die-cut into custom gaskets and seals for equipment flanges, access doors, and other sealing applications.